Technology Transfer and Innovation

Conceptual design of a tourist railcar

A 17m diameter self-supporting GRP tanki cover was modelled using the finite element method (FEM). The results of the finite element analysis (FEA) helped to determine the wall thicknesses.

Once the design had been finalised, the cover was fabricated and tested.

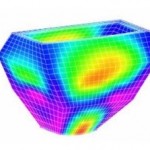

FEA of a 20 ton GRP sugar bin. The design called for a 20% decrease in mass to increase the payload. Once the design and analysis was complete, several bins were fabricated.

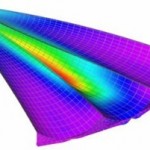

FEA was used here to optimise the wall thicknesses of a GRP evaporator and minimise the cost.

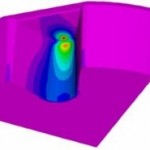

A symmetric FE model of a GRP portable bunded tank used to determine the wall thickness required to support a 1.5 ton vessel containing hazardous chemicals. The design has recently been finalised, the tooling completed and a prototype fabricated.

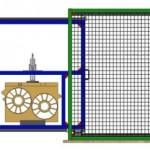

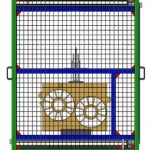

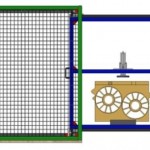

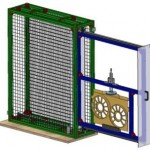

Vibration Jig

Designed for Smiths Manufacturing

Caesar II Piping Analysis

Caesar analysis of GRP ducting exposed to the effects of high temperature and water hammer loads.

Caesar piping analysis model of a GRP piping system used to determine the poptimal locations of supports and expansion loops.

Failure Analysis

An investigation to determine the cause of failure of a large steel impellor clad in polypropylene was carried out. The predominant cause of failure was determined to be the poor quality of the polypropylene welds attaching the flywheel to the outer disk.

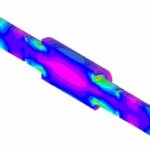

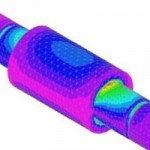

FEA was used to locate stress raisers that were leading to repeated failure of large compressor shafts. The results quickly pinpointed the crack initiators.

An investigation to determine the cause of failure of a cargo block shaft revealed over-loading to be responsible.

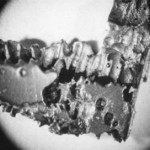

An investigation to determine the cause of corrosive failure at the weld interface connecting two different grades of stainless steel tube was carried out.

The evidence showed that weld decay occurred and, in the presence of sea

Copyright © Technology Station: Reinforced & Moulded Plastics, All Rights Reserved.