Menu

- Spring Graduation Ceremonies 2025

- SRC Online Elections 2025

- Application & Registration Information

- Academic Calendar 2025

- Fees Booklet

- Academic Calendar 2026

- Study Opportunities

- ENVISION2030 Institutional Awards

- Career Leaflets

- Handbooks

- Court Order – Forums Threat

- ENVISION2030

- Why Choose DUT

- “Missing Middle” application form

- NSFAS New Students

- NSFAS

- Autumn Graduation Ceremonies 2025

- Honorary Doctorates

- DUTLink Newsletter

- Lecture Timetable

- Association of Commonwealth Universities

DUTLINK

Our Facebook Page

Facilities

Characterisation Laboratory

Composite Processing Workshop

Environmental Scanning Electron Microscope Laboratory (ESEM)

Mechantronic Laboratory

Strengths Laboratory

Thermal Analysis Laboratory

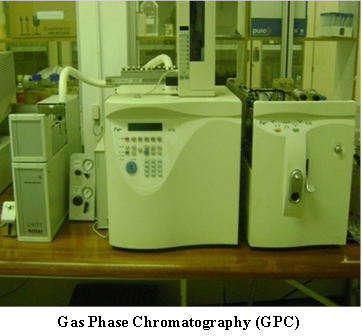

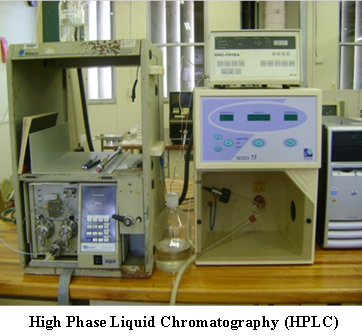

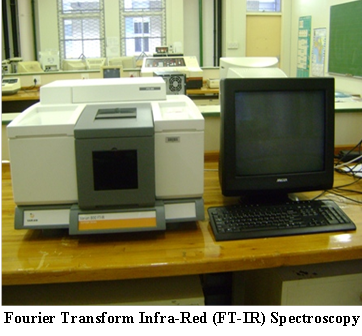

Characterisation Laboratory

This laboratory contains Gas Phase Chromatography (GPC), High Phase Liquid Chromatography (HPLC) and Fourier Transform Infra-Red (FT-IR) Spectroscopy apparatus that are useful in the characterization of polymer and nano particle filled polymers and composites.

|

|

|

|

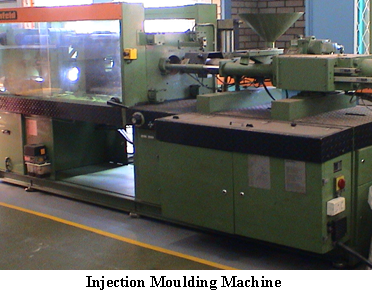

Composite Processing Workshop

The workshop is primarily dedicated to postgraduate students’ and post doctoral fellows’ research projects. Occasionally, undergraduate students also make use of this facility.

The workshop is equipped with facilities for research, sample preparations and prototyping. These facilities include an extruder, injection moulding machine, infra-red heater, hydraulic press, a lathe, milling machines, MIG and TIG welding apparatus, drill presses, and a compressor.

There are other special facilities / tools / equipment for composite materials processing, such as a vacuum pump, electric furnace, magnetic stirrer and heater, and an electronic scale. The workshop also house the raw materials required for composite processing including various types of fibres, diverse resin systems, nanoclays, and consumables. A wide range of supportive hand tools and computing equipment concludes the self-contained nature of this workshop.

|

|

|

|

Environmental Scanning Electron Microscope Laboratory (ESEM)

The faculty of Engineering and the Built Environment has recently acquired an ZEISS EVO HD 15 Environmental Scanning Electron Microscope (ESEM). This instrument allows the user to view samples at higher magnifications than is possible with a light microscope. The unit delivers high definition images from as low as 1 kV up to 30 kV.

The microscope can be used in three modes, namely, high vacuum, variable pressure and extended pressure. The high vacuum mode is usually used for viewing conductive samples such as metals. Non-conductive samples or samples that generate charge such as plastics are examined under the variable pressure mode. In this mode inert gas is pumped into the sample chamber which reduces the charge build-up on the sample. The extended pressure mode is similar to the variable pressure mode and is used to analyse wet samples.

The microscope also has an Energy Dispersive X-ray spectrometer (EDX) and a Wavelength Dispersive X-ray spectrometer (WDX). The EDX system is able to identify the elemental composition of the sample by measuring the amount of energy present in the X-rays emitted by the sample. The WDX works similarly to the EDX with the exception that the detector measures the wavelengths of the emitted X-rays.

Use of the ESEM facility is aimed at industries that include aerospace, naval, geological, construction, automotive, medical, biochemical, and others.

|

|

|

|

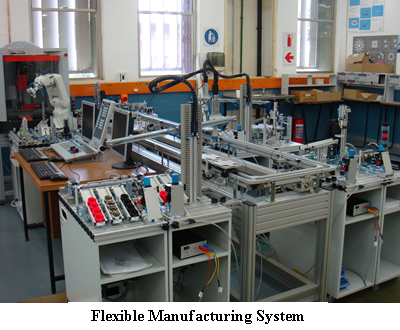

Mechatronic Laboratory

This is a new state-of-the-art facility that DUT has launched. This facility is one of only three in South Africa. The laboratory consists of a Flexible Manufacturing System (FMS), hydraulic and pneumatic workstations, a CNC mill and a CNC lathe.

The FMS is basically a miniature automated manufacturing industry. It can be used to demonstrate the fundamentals of automation and simulation to learners. The system comprises of a conveyer, and, sorting, handling, assembly, testing, distribution, and processing stations. The assembly station uses a robotic arm in conjunction with a CNC mill to facilitate the assembly of components. The manufacture of components can be simulated from start to finish, including assembly processes, without human intervention. The system may be programmed to perform various types of operations.

The hydraulic and pneumatic workstations are capable of handling hydraulic, electro-hydraulic and pneumatic systems. They can also be interfaced with computer software and other electrical controls. Various accessories include a multitude of hydraulic, electro-hydraulic and pneumatic components such as directional valves, logic elements, amplifiers, gauges, etc.

Learners have the opportunity to design and build their own hydraulic and pneumatic circuits. They are also instructed in CNC programming, PLC programming, FMS and robotics.

|

|

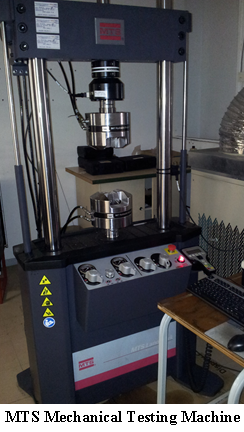

Strengths Laboratory

This laboratory houses a hydraulically actuated MTS mechanical testing machine. The machine is capable of tasks ranging from single-axis tension / compression testing to complex fracture mechanics and multi-axial fatigue testing.

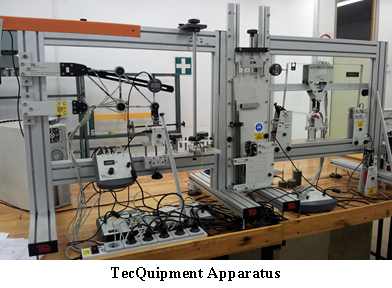

The Strengths of Materials Laboratory also consists of several other equipment including an impact tester, a Lloyds tensile tester, light microscopes, polishers and TecQuipment which is technical teaching apparatus for a variety of experiments.

The mechanical testing performed in this laboratory enables the research group to develop stronger, lighter and more durable materials. The equipment is also used to identify failure mechanisms and for cyclic loading.

|

|

|

|

Thermal Analysis Laboratory

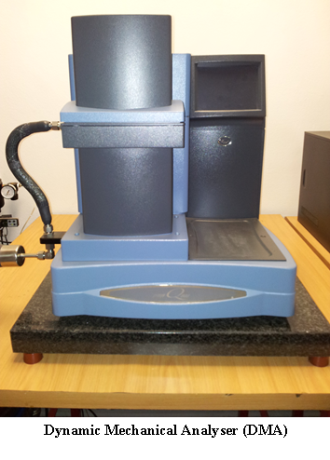

The purpose of this laboratory is to perform thermal analyses on solid, liquid, powder or visco-elastic specimens at various temperature ranges. Currently the laboratory consists of a Dynamic Mechanical Analyser (DMA), and, a simultaneous Differential Scanning Calorimeter (DSC) and Thermo Gravimetric Analyser (TGA).

The DMA is used to determine the storage and loss modulus, tan-delta, static and dynamic forces, and other properties of polymer based structures. Specimens are clamped to a test platform and subjected to cyclic loading over various temperature ranges. Clamping devices include dual/single cantilever, three-point bending, shear sandwich, compression, and tension. The furnace has a temperature range from ambient to 1500 °C; however, this range can be extended to -150 °C by means of a cryogenic unit.

The simultaneous DSC and TGA apparatus is used for investigating the differential heat flow and weight change in solid or liquid specimens. The apparatus has a dual beam balance with a sample capacity of 200 mg, and a furnace with a temperature range from ambient to 1500 °C. Currently, samples may be tested in either a nitrogen or oxygen environment, or a combination of these. The apparatus also has the capability of conducting tests in hazardous gas environments. Sample holders consist of platinum, aluminium and alumina.

The above equipment may be managed by either the onboard controller or via computer software. Analysis software is also available for post-processing of raw data.

|

|